Installation

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

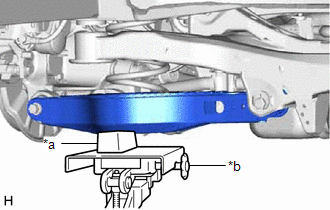

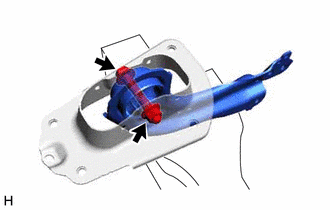

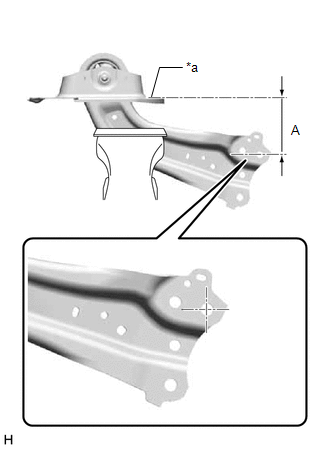

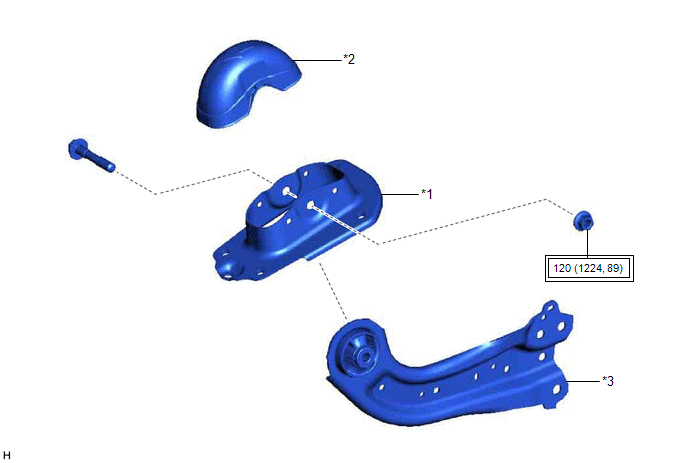

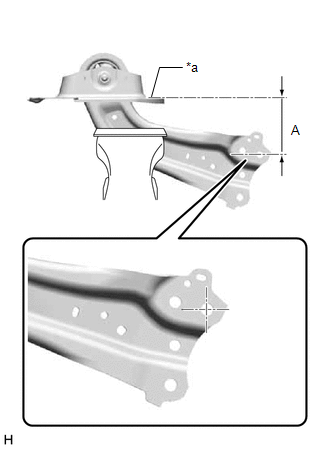

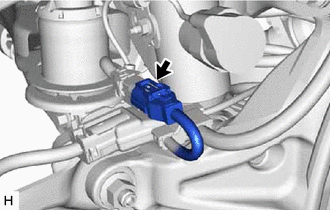

1. INSTALL REAR SUSPENSION ARM BRACKET

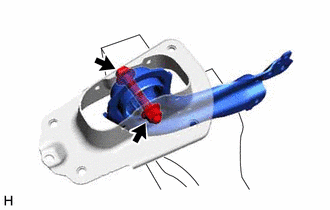

| (a) Temporarily install the rear suspension arm bracket to the rear trailing arm assembly with the bolt and nut.

NOTICE:

- Because the bolt has its own stopper, do not turn the bolt. Tighten the nut with the bolt secured.

- Insert the bolt from the inside of the vehicle.

| |

| (b) Position the rear trailing arm assembly as shown in the illustration.

Reference Length (A): 120 mm (4.72 in.) |

|

|

*a | Upper Surface of Rear Suspension Arm Bracket | | |

(c) Fully tighten the nut.

Torque:

120 N·m {1224 kgf·cm, 89 ft·lbf}

NOTICE:

Because the bolt has its own stopper, do not turn the bolt. Tighten the nut with the bolt secured.

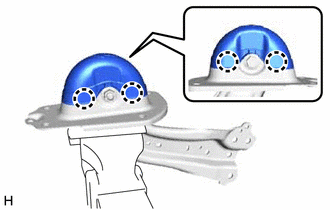

2. INSTALL REAR SUSPENSION ARM COVER

(a) Engage the 4 claws and install the rear suspension arm cover.

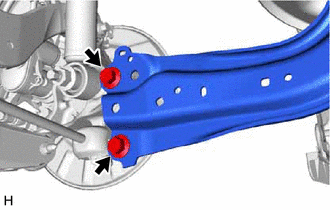

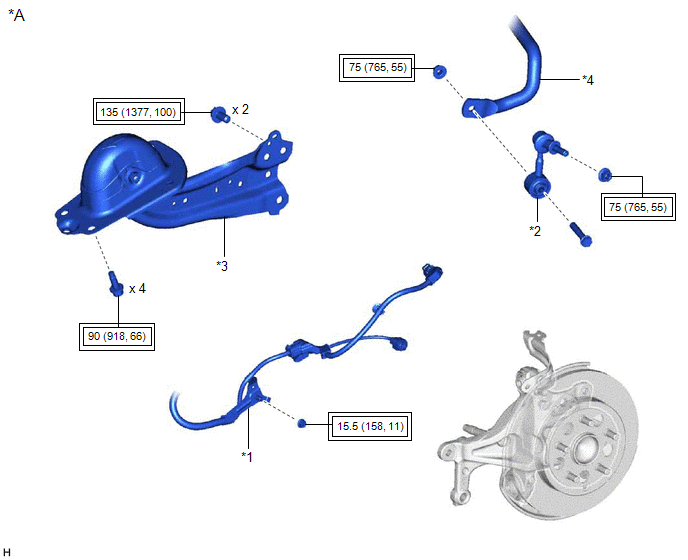

3. INSTALL REAR TRAILING ARM ASSEMBLY

(a) Using a transmission jack and a wooden block, support the rear No. 2 suspension arm assembly.

NOTICE:

- When jacking up the rear No. 2 suspension arm assembly, be sure to jack it up slowly.

- Make sure to perform this operation with the vehicle kept as low as possible.

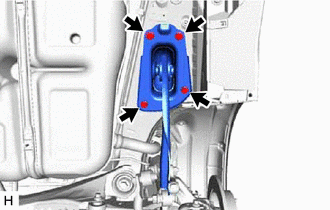

(b) Install the rear trailing arm assembly to the vehicle with the 4 bolts.

Torque:

90 N·m {918 kgf·cm, 66 ft·lbf}

(c) Install the rear trailing arm assembly to the rear axle carrier sub-assembly with the 2 bolts.

Torque:

135 N·m {1377 kgf·cm, 100 ft·lbf}

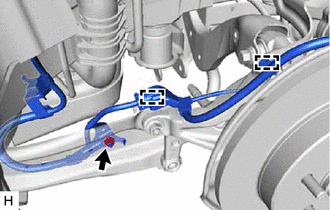

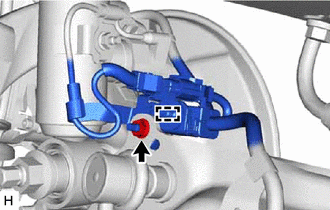

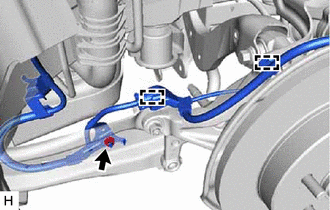

4. INSTALL NO. 2 PARKING BRAKE WIRE ASSEMBLY (w/o AVS)

| (a) Install the No. 2 parking brake wire assembly to the rear trailing arm assembly with the nut.

Torque: 15.5 N·m {158 kgf·cm, 11 ft·lbf} | |

(b) Engage the 2 clamps.

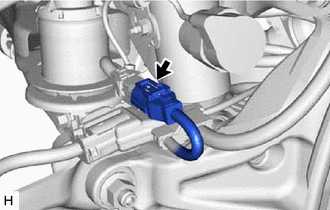

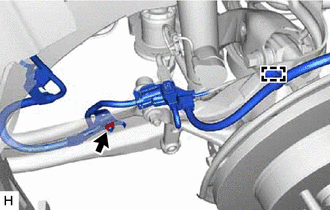

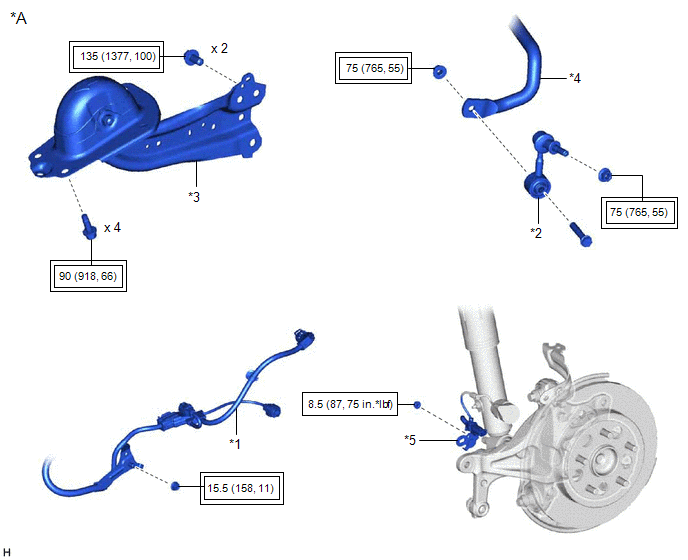

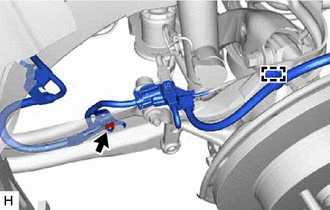

5. INSTALL NO. 2 PARKING BRAKE WIRE ASSEMBLY (w/ AVS)

| (a) Install the No. 2 parking brake wire assembly to the rear trailing arm assembly with the nut.

Torque: 15.5 N·m {158 kgf·cm, 11 ft·lbf} | |

(b) Engage the clamp.

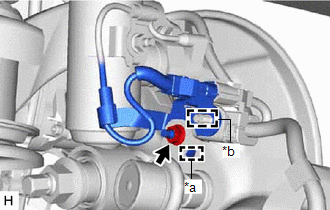

|

(c) Engage the guide and install the wire harness bracket. | |

(d) Install the nut.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

(e) Engage the clamp and install the No. 2 parking brake wire assembly to the wire harness bracket.

| (f) Connect the connector. | |

6. INSTALL REAR STABILIZER LINK ASSEMBLY

Click here

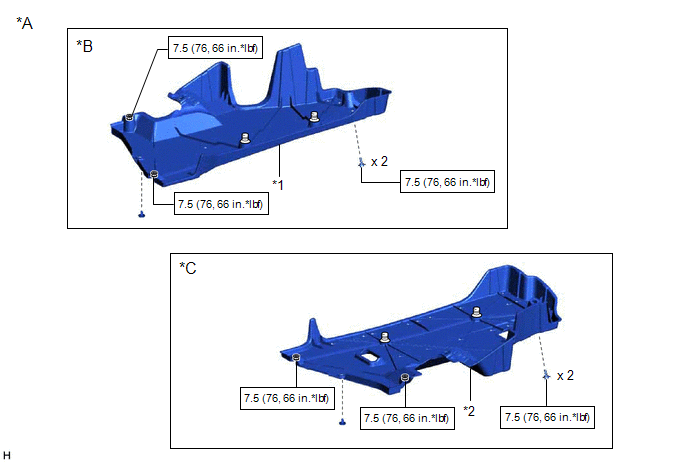

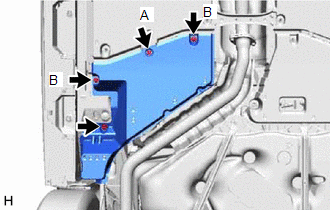

7. INSTALL NO. 1 FLOOR UNDER COVER (for HV Model)

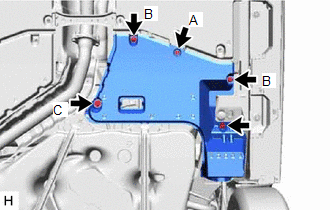

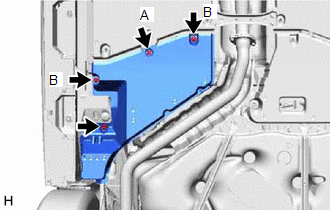

| (a) for RH Side: (1) Install the No. 1 floor under cover with the 2 grommets (B).

Torque: Grommet (B) : 7.5 N·m {76 kgf·cm, 66 in·lbf}

(2) Install the bolt and clip (A). Torque: Bolt : 7.5 N·m {76 kgf·cm, 66 in·lbf} |

|

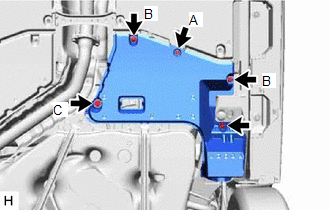

8. INSTALL NO. 2 FLOOR UNDER COVER (for HV Model)

| (a) for LH Side: (1) Install the No. 2 floor under cover with the 2 grommets (B) and clip (C).

Torque: Grommet (B) : 7.5 N·m {76 kgf·cm, 66 in·lbf}

(2) Install the bolt and clip (A). Torque: Bolt : 7.5 N·m {76 kgf·cm, 66 in·lbf} |

|

9. INSTALL NO. 1 FLOOR UNDER COVER (for Gasoline Model)

(a) for RH Side:

Click here

10. INSTALL NO. 2 FLOOR UNDER COVER (for Gasoline Model)

(a) for LH Side:

Click here

11. INSTALL REAR WHEEL

Click here

12. INSPECT AND ADJUST REAR WHEEL ALIGNMENT

Click here

13. PERFORM INITIALIZATION

for Gasoline Model:

- Intelligent Clearance Sonar System

- Intuitive Parking Assist System

|

|

|

Parking Assist Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

|

Panoramic View Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

for HV Model:

- Intelligent Clearance Sonar System

- Intuitive Parking Assist System

|

|

|

Parking Assist Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

|

Panoramic View Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

Removal

REMOVAL

CAUTION / NOTICE / HINT

The

necessary procedures (adjustment, calibration, initialization, or

registration) that must be performed after parts are removed and

installed, or replaced during rear trailing arm assembly

removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced (for Gasoline Model:) |

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

| Rear wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

- VSC disabled or malfunctioning

- DTCs are output

- Slip indicator light illuminated

- ABS warning light illuminated

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement.) |

- Measure ultrasonic sensor detection angle

- Ultrasonic sensor detection angle registration

|

- Intelligent Clearance Sonar System

- Intuitive Parking Assist System

|

|

|

Rear television camera assembly optical axis adjustment (Back camera position setting) |

Parking Assist Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

- Parking assist ECU initialization

- Adjust steering angle

- Television camera assembly optical axis adjustment (Back camera position setting)

| Panoramic View Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

Necessary Procedures After Parts Removed/Installed/Replaced (for HV Model:) |

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

| Rear wheel alignment adjustment |

- Clear zero point calibration data.

- Perform yaw rate and acceleration sensor zero point calibration.

|

- DTCs are stored

- ABS warning light illuminates

- Brake warning light / yellow (minor malfunction) illuminates

- Slip indicator light illuminates

- VSC disabled or malfunctions

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement.) |

- Measure ultrasonic sensor detection angle

- Ultrasonic sensor detection angle registration

|

- Intelligent Clearance Sonar System

- Intuitive Parking Assist System

|

|

|

Rear television camera assembly optical axis adjustment (Back camera position setting) |

Parking Assist Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

- Parking assist ECU initialization

- Adjust steering angle

- Television camera assembly optical axis adjustment (Back camera position setting)

| Panoramic View Monitor System |

for Initialization for Initialization

for Calibration for Calibration |

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE REAR WHEEL

Click here

2. REMOVE NO. 2 FLOOR UNDER COVER (for Gasoline Model)

(a) for LH Side:

Click here

3. REMOVE NO. 1 FLOOR UNDER COVER (for Gasoline Model)

(a) for RH Side:

Click here

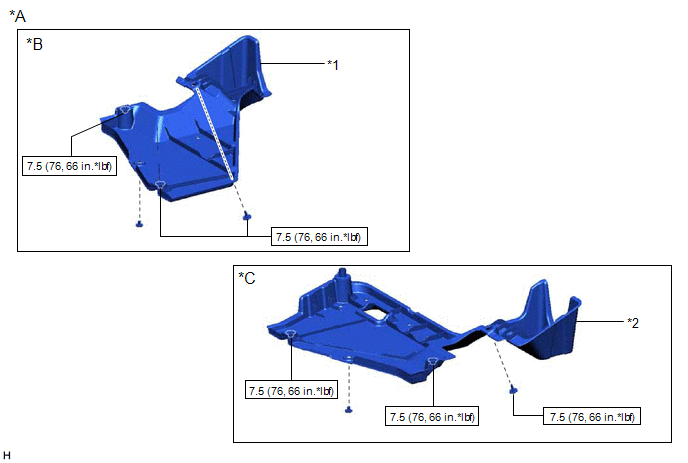

4. REMOVE NO. 2 FLOOR UNDER COVER (for HV Model)

| (a) for LH Side: (1) Remove the bolt and clip (A). (2) Disengage the 2 grommets (B) and clip (C) to remove the No. 2 floor under cover. |

|

5. REMOVE NO. 1 FLOOR UNDER COVER (for HV Model)

| (a) for RH Side: (1) Remove the bolt and clip (A). (2) Disengage the 2 grommets (B) to remove the No. 1 floor under cover. |

|

6. SEPARATE NO. 2 PARKING BRAKE WIRE ASSEMBLY (w/o AVS)

| (a) Disengage the 2 clamps. | |

(b) Remove the nut and separate the No. 2 parking brake wire assembly from the rear trailing arm assembly.

7. SEPARATE NO. 2 PARKING BRAKE WIRE ASSEMBLY (w/ AVS)

| (a) Disconnect the connector. | |

| (b) Remove the nut and disengage the clamp. | |

(d) Remove the nut and separate the No. 2 parking brake wire assembly from the rear trailing arm assembly.

8. REMOVE REAR STABILIZER LINK ASSEMBLY

Click here

9. REMOVE REAR TRAILING ARM ASSEMBLY

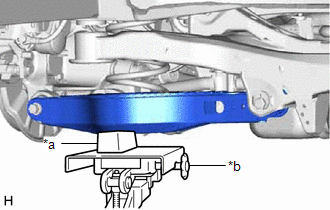

| (a) Using a transmission jack and a wooden block, support the rear No. 2 suspension arm assembly.

NOTICE:

- When jacking up the rear No. 2 suspension arm assembly, be sure to jack it up slowly.

- Make sure to perform this operation with the vehicle kept as low as possible.

|

|

|

*a | Wooden Block | |

*b | Transmission Jack | | |

| (b) Remove the 2 bolts and separate the rear trailing arm assembly from the rear axle carrier sub-assembly. |

|

| (c) Remove the 4 bolts and rear trailing arm assembly. |

|

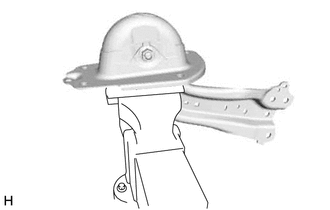

10. REMOVE REAR SUSPENSION ARM COVER

| (a) Secure the rear trailing arm assembly in a vise using aluminum plates.

NOTICE: Do not overtighten the vise. | |

| (b) Disengage the 4 claws and remove the rear suspension arm cover. |

|

11. REMOVE REAR SUSPENSION ARM BRACKET

| (a) Remove the bolt, nut and rear suspension arm bracket from the rear trailing arm assembly.

NOTICE: Because the bolt has its own stopper, do not turn the bolt. Loosen the nut with the bolt secured. |

|

for Initialization

for Initialization for Calibration

for Calibration for Initialization

for Initialization for Calibration

for Calibration

for Initialization

for Initialization for Calibration

for Calibration for Initialization

for Initialization for Calibration

for Calibration

for Initialization

for Initialization for Calibration

for Calibration for Initialization

for Initialization for Calibration

for Calibration

for Initialization

for Initialization for Calibration

for Calibration for Initialization

for Initialization for Calibration

for Calibration